Spray dryer Model SODA-12-for Pharma&Food use

Time: 2020-05-24

Time: 2020-05-24

When drying products with low softening-point and strong hygroscopicity, the general spray dryer type will be likely to have caramel-like powder sticked on the inner wall of chamber and powder bucket under the cyclone. Some of these products even cannot be collected as dried powder.

In order to solve this problem, it is necessary to add much additives such as dextrin and starch in feed procedure before drying. Even so, inner-wall adhesion and coking of products near the hot-air-disperser or clogging in the ducts still happen after serval hours’ operation, which leads to the result that low product quality due to long-time adhering and frequent but unnecessary shutdown cleaning.

As mentioned above, the general spray dryer faces problems of poor yield, waste of energy and reduction of capacity utilization for these products. We, Shanghai Ohkawara designed a series of spray dryer as a solution, which Model SODA-12 is the smallest type in this series.

Features

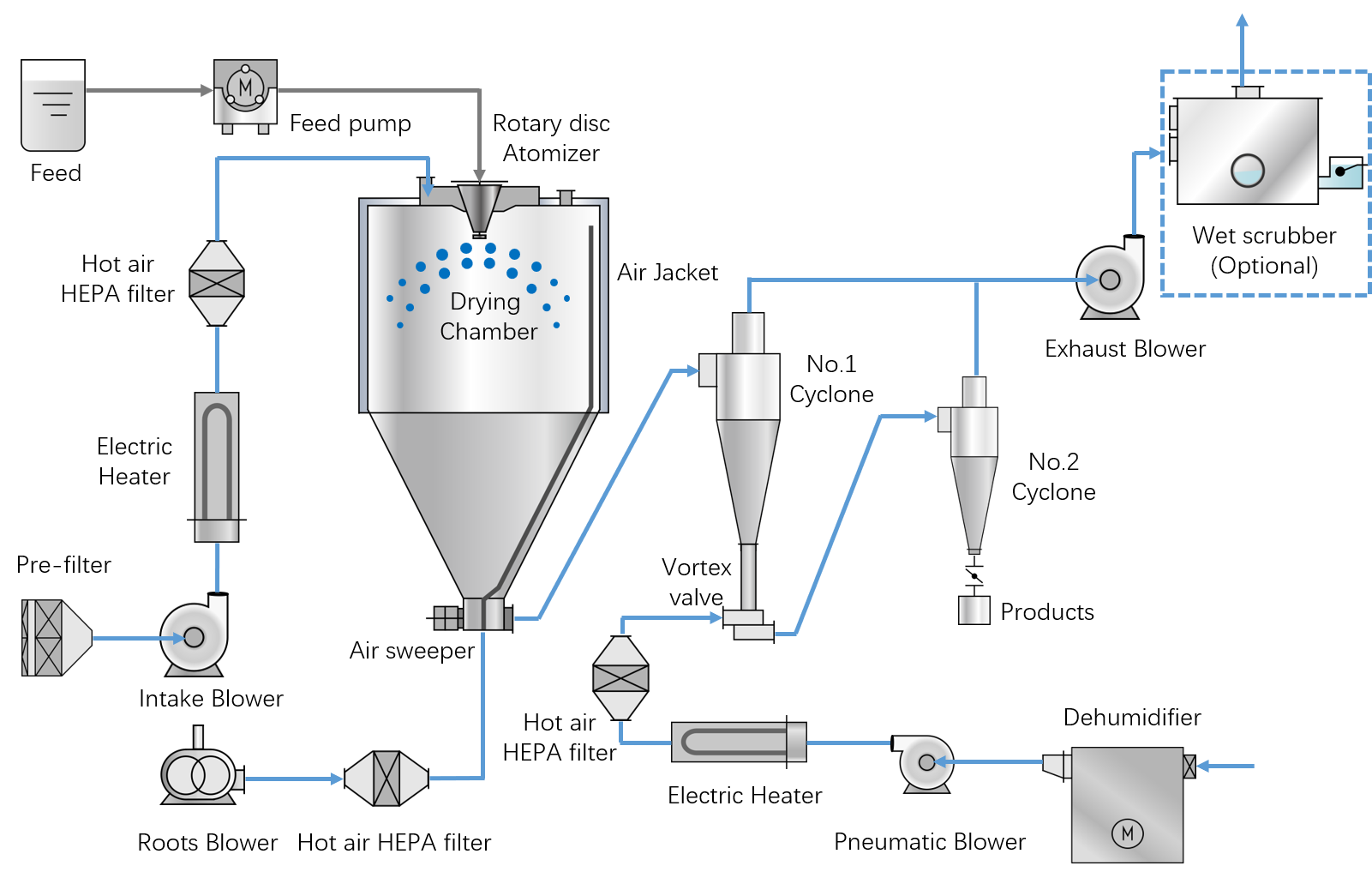

1. Compact structure, nice externality, air disperser washable, inlet & outlet temperature adjustable.

2. Air jacket at drying chamber’s inner wall and top part to prevent product from melting and adhering.

3.Air sweeper inside drying chamber to take away or reduce wall sticking.

4.Pneumatic system with dehumidified air so as to adjust product temperature as well as preventing moisture absorption and clumping.

5.GMP compliable. Cleanliness class of dried air better than 100 thousand. Also easy to clean (manual cleaning) and easy to operate (automatic control system).

Model SODA-12 is widely used by domestic Pharmaceuticals (including Traditional Chinese Medicine), Foods users for R&D and small-scale production.

Flow chart for reference

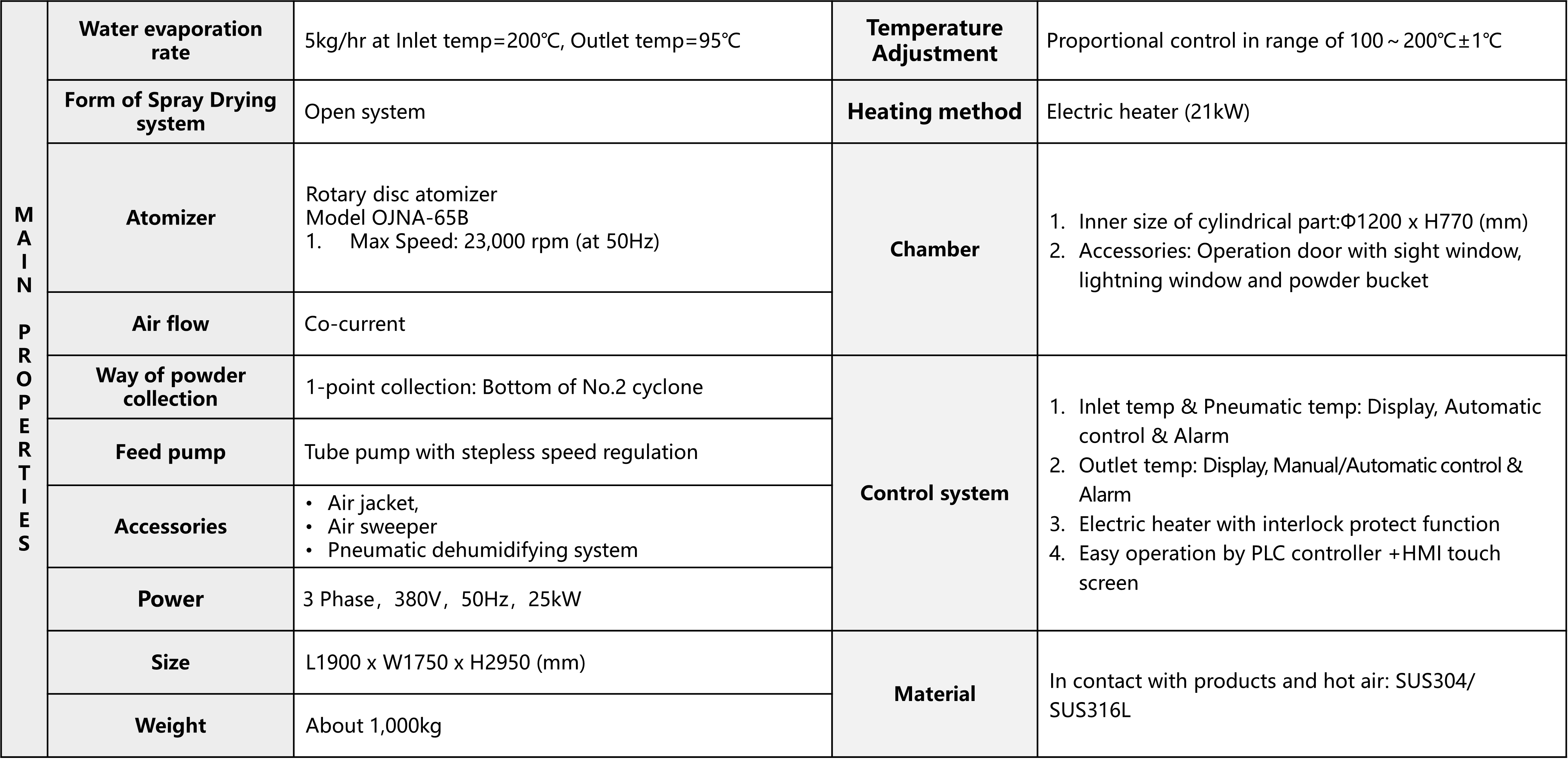

Technical Specifications