Spray coolers

Time: 2021-04-09

Time: 2021-04-09

Closed-cycle spray cooler is a system which enables the collection of spherical particles by making the spray of fine particles (solid material heated above the melting point) cooled rapidly by cool air. Also, by mixing one material as core into melted material we can create microcapsules.

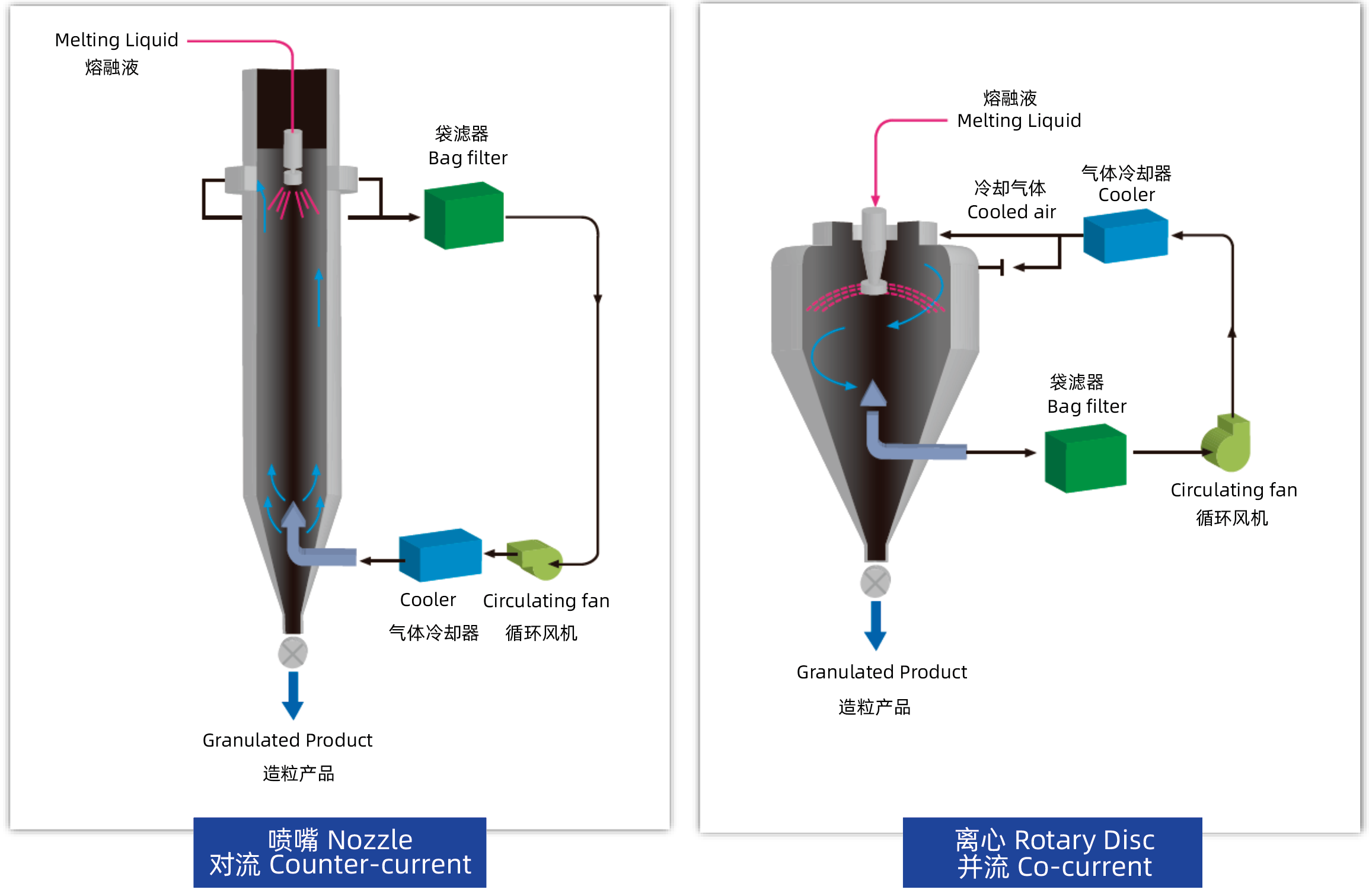

Process of spray cooling

Features

1.Spherical product appearance

A)Uniform particles

B)Sharp PSD (particle size diameter)

C)No dust & dust flying

D) No oxidize & Discolor

2. Excellent flowability, superior mechanical strength and less handling damage.

A)Easier to achieve continuity, automation and labor reduction in feeding, batching, mixing, measuring and packaging.

B)Improve the solubility

C)Better work conditions

3.Easy Operation and Best for continuous granulation in large amounts

4.Possibility of automatic operation by the collocation of front and following process

5.A closed & negative pressure nitrogen system to ensure the safe operation of the whole system in consideration of the flammability and dust explosion of products.

Applications

Composition of closed-cycle spray cooler

Features of different atomizers used on Spray Cooler

Atomizer | Medium particle size | RPM/ Pressure | Viscosity | PSD | Chamber diameter | Chamber height |

Rotary disc | 50~200μ | 4,000~ 20,000rpm | 1x10-2 ~20Pa·s | Sharp | Large | Low |

Pressure nozzle | 100~600μ | 0.5~3MPa | 1x10-2 ~1Pa·s | Broad | Medium | Medium |

Dripping nozzle | 600~2,000μ | <0.2MPa | 1x10-3 ~1x10-1Pa·s | Sharp | Small | Tall |

Air-assisted pressure nozzle | 30~500μ | <3MPa | 1x10-2 ~1.5Pa·s | Medium | Meduim | Medium |